Project A7 - Catalysis

Catalytic carbon monoxide oxidation over potassium-doped manganese dioxide nanoparticles synthesized by spray drying

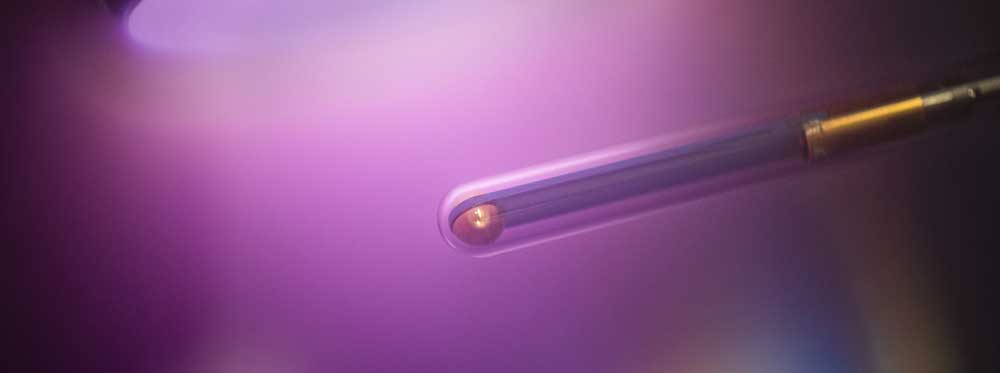

One of the major objectives of the CRC 1316 is the investigation and understanding of the complex interactions between a non-thermal plasma and heterogeneous catalysts. The first results of project A7 describing the thermocatalytic oxidation of CO over MnO2 catalysts were recently published in Emission Control Science and Technology. Particularly, the effect of the incorporated alkali ions on K+ and Na+ on the structural properties and the catalytic performance was emphasized to derive structure-activity correlations.

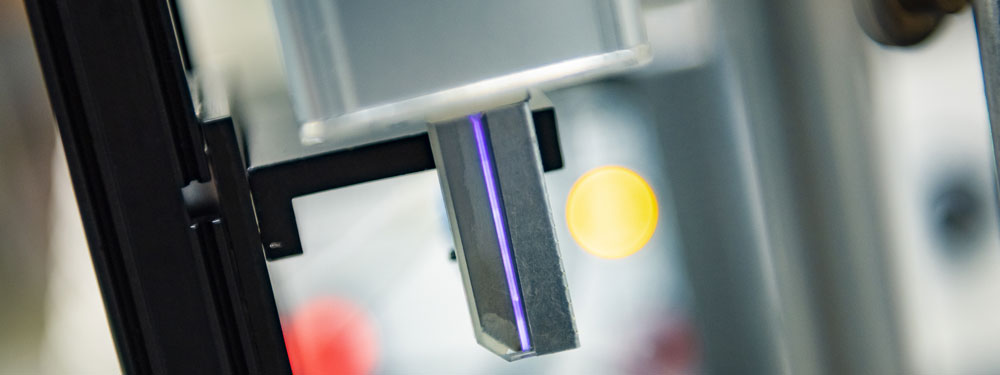

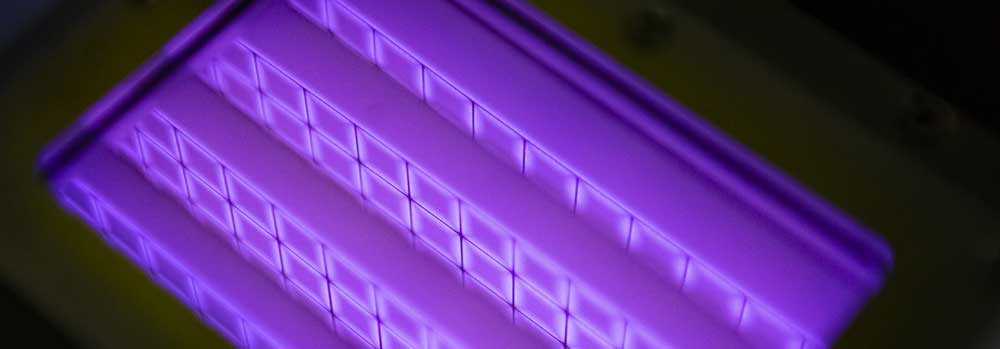

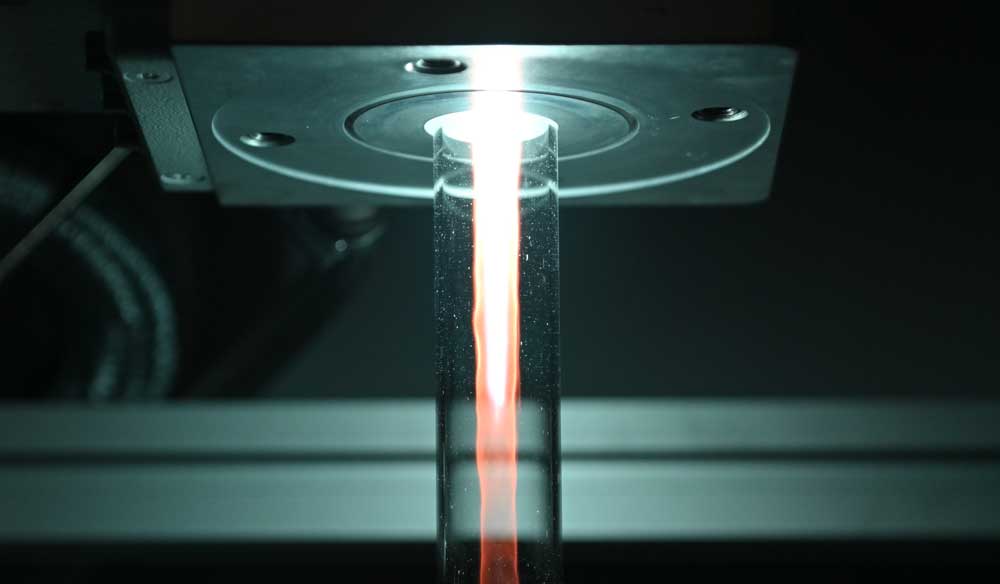

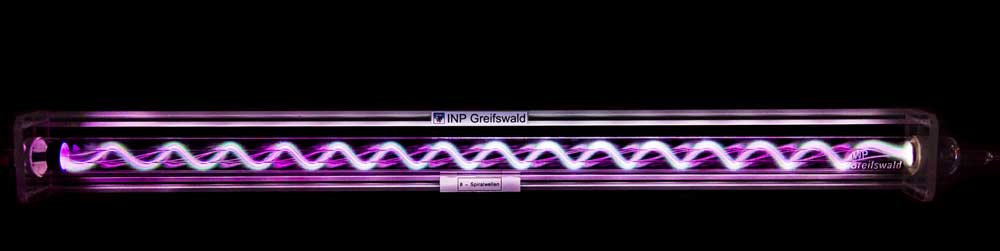

The MnO2 catalysts were synthesized by a semi-continuous spray drying procedure based on the comproportionation reaction of Mn(NO3)2 and KMnO4. Solutions of both compounds were continuously mixed in a micromixer and the emerging suspension was rapidly quenched by spray drying to inhibit further particle growth. In order to exchange the K+ ions by Na+ ions, NaMnO4 was used instead of KMnO4 during the synthesis. After washing and drying of the catalysts a fine brown powder was obtained, which was used as prepared or calcined at 450°C or 500°C for 4 h in synthetic air.

As shown by the XPS results and TPO profiles Mn (IV) is the predominant oxidation state of all samples prior to calcination proving that all catalysts consist of MnO2. However, the XRD patterns of the uncalcined catalysts reveal an X-ray amorphous structure preventing a more in-depth phase identification. After calcination the phase structure strongly depends on the type and amount of the incorporated alkali ion. The presence of K+ promotes the formation of crystalline alpha-MnO2 and stabilizes its tunnel structure up to temperatures of 500°C. Lower amounts of K+ or the exchange with Na+ lead to less crystalline phases after calcination at 450°C and to the formation of crystalline alpha-Mn2O3 after calcination at 500°C.

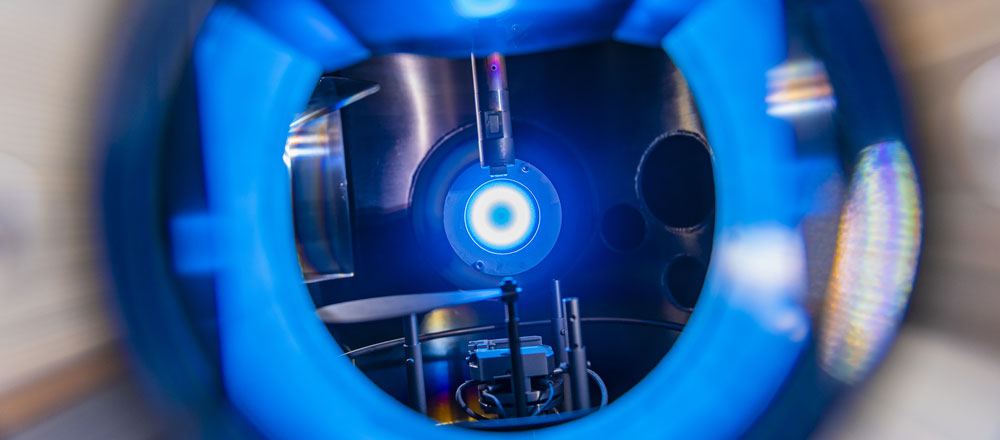

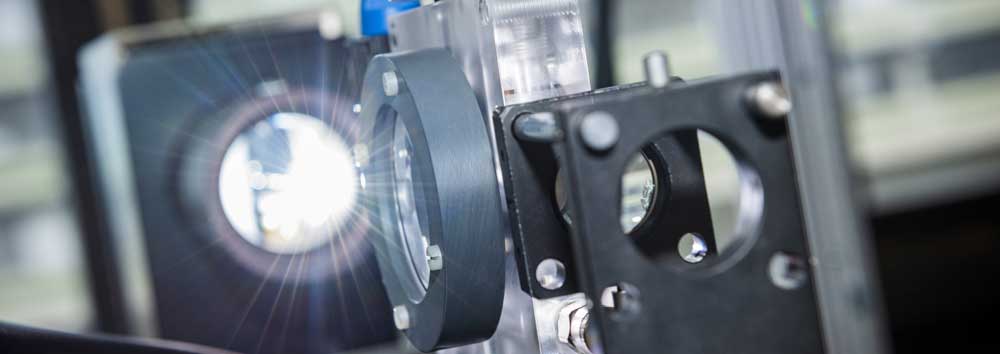

The catalytic CO oxidation was performed in a microreactor set up equipped with a non-dispersive IR detector. All uncalcined catalysts revealed a similar catalytic performance regardless of the type or amount of the incorporated alkali ion. Even though the specific surface area of the catalyst decreased from 77 m2/g to 37 m2/g during calcination the pure alpha-MnO2 phase exhibited a superior catalytic activity. Over alpha-MnO2 the temperature at which full conversion was achieved was shifted towards lower temperatures by more than 100°C. In contrast the catalyst containing alpha-Mn2O3 show a catalytic activity similar to the uncalcined catalysts indicating that not only the higher degree of crystallinity but also the structural properties of alpha-MnO2 cause its high catalytic activity. The incorporation of K+ ions is required to stabilize the tunnel structure of alpha-MnO2